L.D. Beston supplies clutches and brakes for use in the mining industry, oil and gas, metalworking, can making, paper, grinding, and marine applications. Bestons distributes US-based Eaton Airflex and German-manufactured Ortlinghaus to provide a range of superior-quality products. Contact us today to discuss which product best suits your industrial power transmission requirements.

Airflex-Danfoss-Eaton Clutches and Brakes

Bestons are Australian distributors of industrial clutches and brakes from respected US company Airflex-Danfoss-Eaton (previously Eaton-Airflex). These quality parts are used throughout industry around the world. They can be found on all types of machinery - from equipment that mines raw materials to the machines that produce finished products.

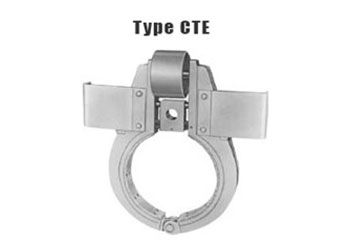

Constricting Clutches and Brakes

Expanding Clutches and Brakes

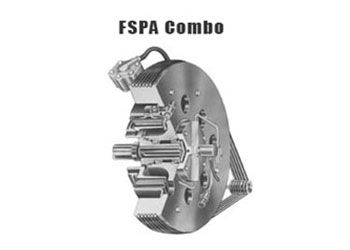

Multiple Disc Clutches and Brakes

Eaton-Airflex AS and AR clutches are typically used in:

- Synchronising

- Indexing

- Speed changing

- Marine main propulsion

- Winch applications

Airflex hydraulic clutches are multiple-disc units available in stationary or rotating cylinder design. They are intended for use with a spray, splash, or through-the-shaft lubricating system, where high speeds are encountered and a high torque/small envelope ratio is required. They are also suitable for air actuation.

Type AS utilises a bearing-mounted, stationary actuating cylinder, which permits a direct external connection to the clutch. The AS design eliminates any centrifugal head on the actuating fluid, which could prevent clutch disengagement.

Torque capacities up to 26,000 lb-in, 2,550 N-m.

Air Cooled Clutches and Brakes

Clutch/Brake Packages

Spring-Applied Brakes

Water Cooled Brakes

Rotor Seal and Quick Release Valves

Ortlinghaus Brakes and Clutches

Bestons are Australian distributors of industrial brakes and clutches from a leading specialist in the industry, Ortlinghaus of Germany. These quality parts are used throughout industry around the world.

Discuss your industrial power transmission needs with us by calling 02 9662 6222.